Slip Sheets: Giving Pallets the Slip

As the material handling industry evolves, one area that continues to grow is the use of slip sheets to transport and handle products rather than the use of traditional pallets.

What is a Slip Sheet?

Slip sheets are thin sheets made of plastic, paper, or corrugated material that come in a variety of shapes and sizes to fit a range of needs. Similar to a pallet, they are placed underneath a load and are used to push or pull the load on and off of the forklift’s forks or platens.

Slip Sheet Attachments

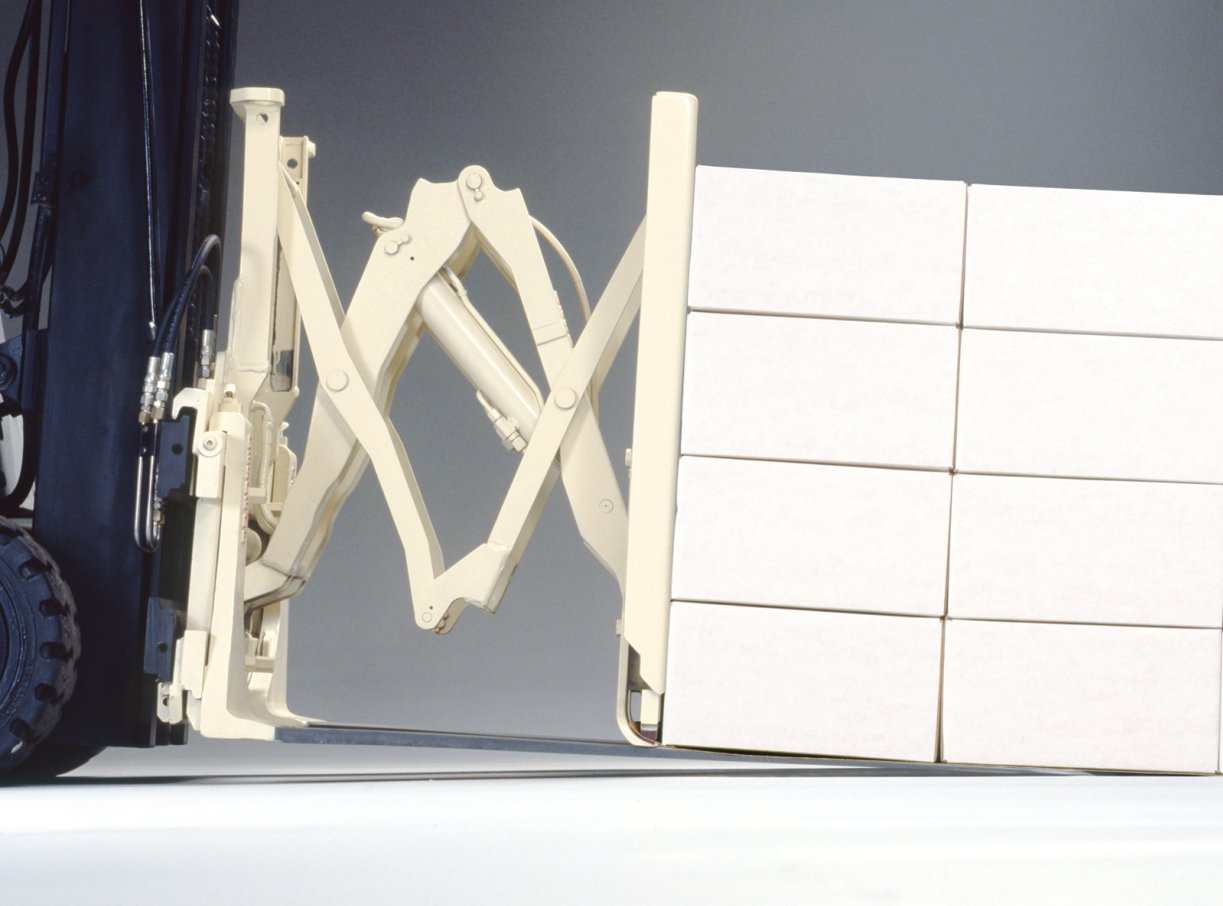

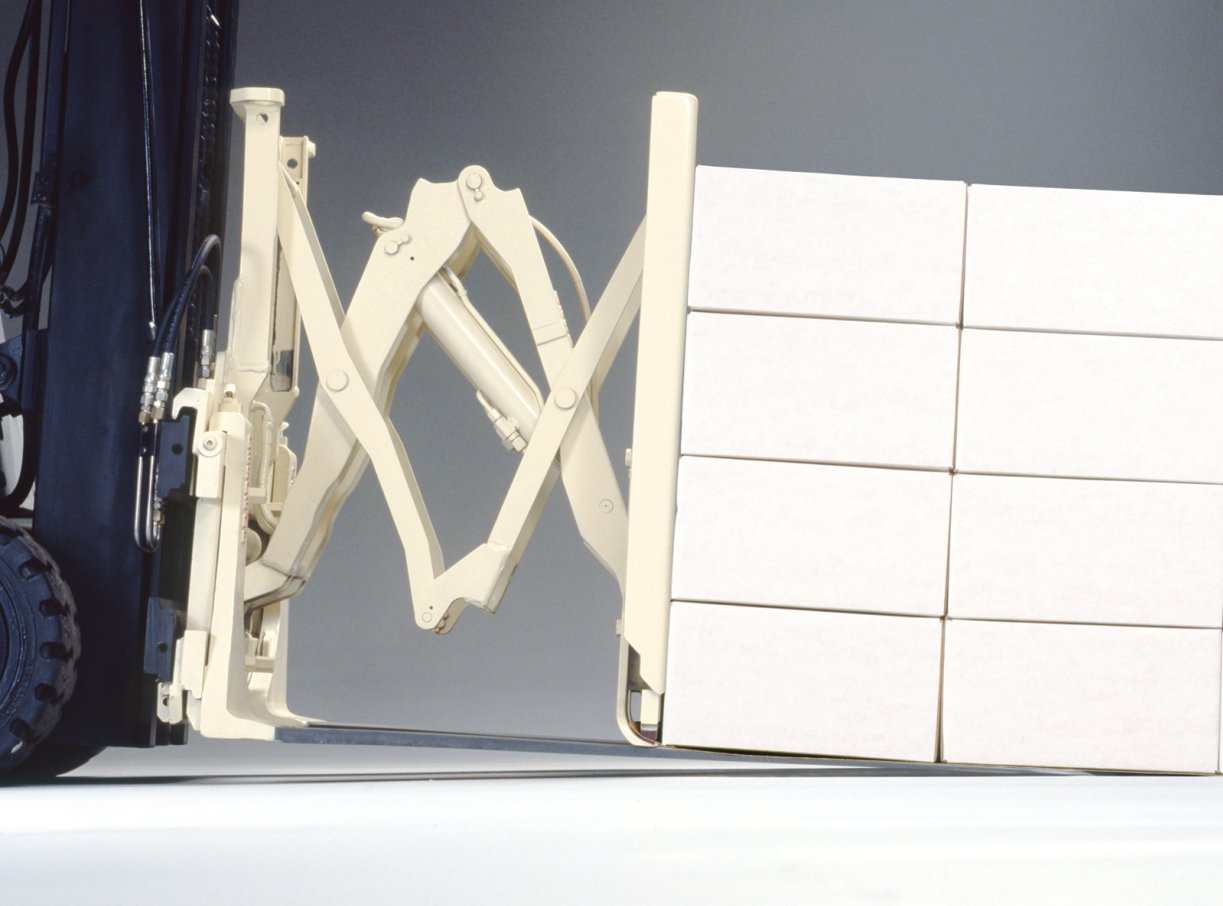

Two different types of attachments are typically used to handle slip sheets. The first is a push/pull attachment that clamps onto the sheet and pulls the sheet and product load onto the platens (platens are essentially wider, thinner forks that come in different shapes and sizes). A gripper jaw at the bottom of the face-plate automatically closes at the end of the stroke and opens at the beginning so that only one hydraulic function is needed to grab and release the load using the sheet.

Above: Push/pull attachment engaging with a slip sheet and pulling the load onto the platens (Credit: Cascade Corporation)

Roller forks are a second type of attachment. Just as the name implies, these forks have multiple sets of rollers spanning across them, which help to roll the load up onto the forks. This type of attachment can also be used without slip sheets depending on the type of load.

Regardless of the attachment you’re using, slip sheets are becoming more and more popular as companies start to realize their potential for return on investment.

Slip Sheets Vs. Pallets

Slip sheets also offer a significant number of advantages over pallets, including:

- Initial cost – Purchasing slip sheets costs significantly less than purchasing pallets. Many pallets can cost more than $10 per unit to purchase while slip sheets will only run you approximately $1 apiece.

- Storage cost – Due to their very slim nature, slip sheets take up significantly less storage space than pallets.

- Transportation cost – Reduced storage space and a lightweight design can greatly reduce transportation costs.

- Labor cost – Slip sheets are easily disposed of and require less labor to be picked up or moved around in a facility. They also save your employees a significant amount of time that would be spent floor loading products onto a trailer or off of a pallet.

- Environmental Impact – Since most slip sheets are easily recyclable, they are often more environmentally friendly than traditional wooden pallets that often end up in landfills.

Slip sheets are a great alternative to pallets in many applications, particularly for loading and unloading trailers and for general warehousing. They, however, aren’t a practical alternative for all types of applications. Non-homogeneous and disproportionate loads aren’t typically ideal for being handled on a slip sheet. Low throughput applications may not be able to justify the return on investment that slip sheets can provide due to high initial cost for the attachment.

Your local, authorized Toyota dealer can help you determine if slip sheets are the right product for you. Make sure to consult them prior to making any major changes to your operation so they can work to provide you with the best solution possible.