Creating a Lean Environment

Why Choose Toyota Lean Management?

Toyota Lean Management draws on practices of standardized process, visual management, unified objective-setting, and continuous improvement to deliver business successes including:

- Improved quality

- Shortened cycle times

- Higher throughput

- Better delivery-times

- Enhanced efficiency

- Reinforced company culture

Work with a Toyota Lean Management Advisor

You can enjoy an intimate tour of our facility in Columbus, IN – focusing on lean tools, culture, and attending daily management meetings.

Toyota Lean Management Advisors can come to your facility to observe and recommend next steps on your lean journey.

Our “Basics of TLM” course will help you understand the real purpose of lean and the value of 5S, visualization, standard work, and Just-in-Time inventory management through impactful teaching and hands-on exercises. This can be completed either at your facility or at our Columbus, IN factory.

The 3-day course in Columbus, IN, incorporates all of the elements of the 1-day course, but also digs deeper into lean topics and culture and allows you to see practical lean examples in our factory firsthand. Management or first-line supervisors will benefit most.

Integrating TLM

Building Successful Infrastructure

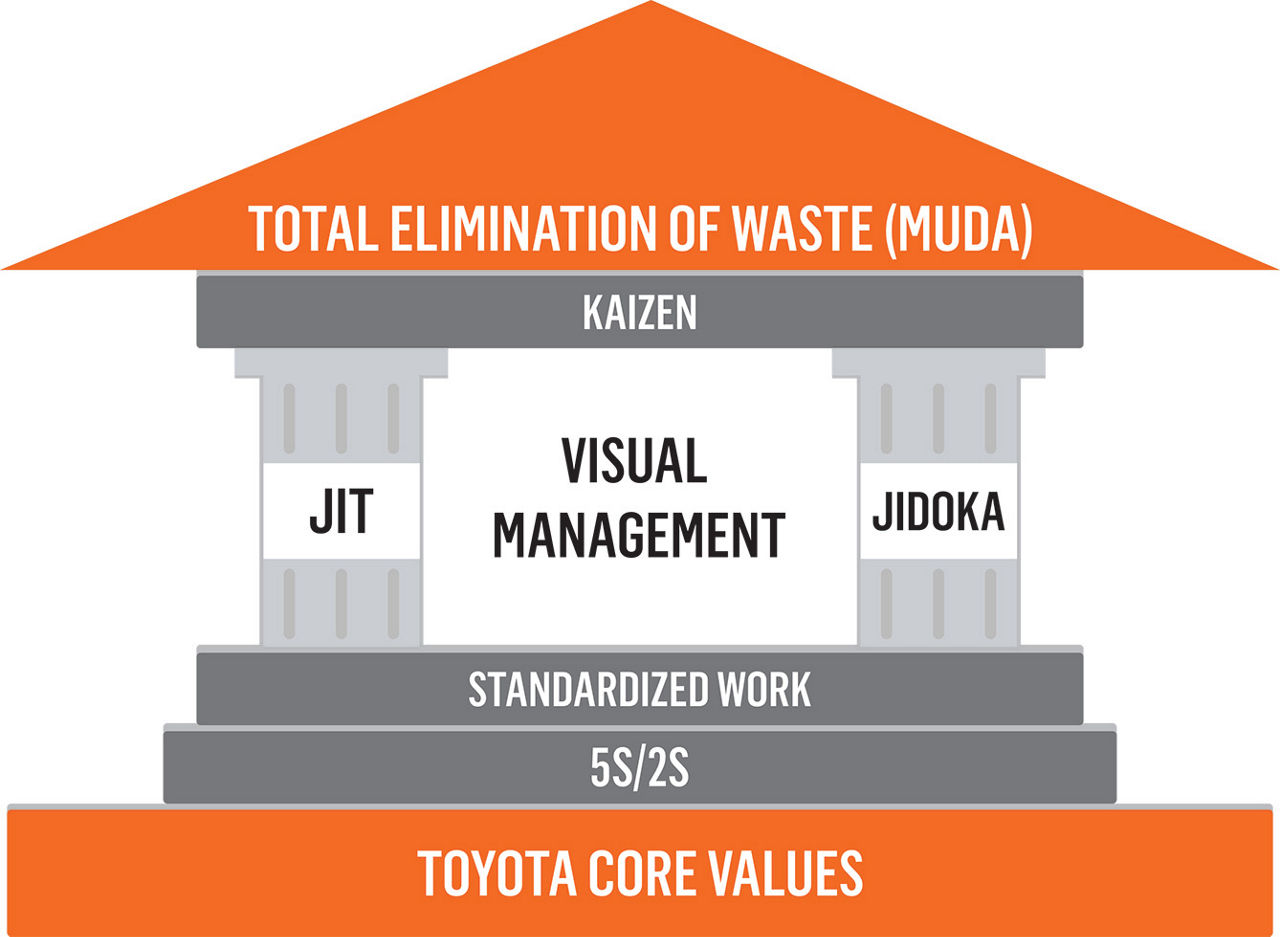

Toyota Lean Management is aimed at the total elimination of waste and is best achieved by constructing your operation with a firm commitment to sustainable processes. It’s like building a house situated on a firm bedrock of core values. On that bedrock are the repeatable management practices of Toyota Lean Management, including 5s, standardized work, and other valuable management techniques that uphold successful elimination of waste.

When you work with Toyota to install Toyota Lean Management as your business management practice, you’ll get a firm understanding of both the concept and execution of these techniques – all engineered to place you on a path to sustained success.

5s to Reduce Waste

Toyota Lean Management rests on a foundation of waste reduction techniques known as 5S, a commonly used practice that Toyota has ingrained as part of the core reasons we continue to be successful, year after year. Each practice in 5S, when repeated and applied continuously, can help to enhance your business efficiency and the quality of your product or activity.

- Sort

- Systematize

- Shine

- Standardize

- Sustain

Sort

Sorting means removing all unnecessary items from the work area, and it can be applied in any business setting. While it may be tools in a shop, it can also mean eliminating unnecessary data points or reports.

Systematize

When everything has a place and everything is in its place, you have effectively systematized your operations. Organize the important items such that you may quickly and efficiently retrieve them to support the ideal process of work. Think flow.

Shine

Clean, so problems can be identified as you work. Abnormal conditions should stand out. Associates should be empowered to solve problems such that the integrity of your systematization is maintained.

Standardize

Document the current work standard. While you can always improve the standard, document the best-known way to accomplish the task. There can be no improvement without a standard – you must have a clear markup of what has been done in order to do it better.

Sustain

Maintain consistency and strive for continued improvement (kaizen). If you have found a successful, systematic process that is easily understandable for associates, you must be sure to repeat that process. It is the responsibility of all associates to sustain successful process.

Empowering People, Solving Processes

The distinction between Toyota Lean Management and other forms of management is its focus of the growth and empowerment of people. Once a good process is established, it’s imperative you give associates the opportunity to recognize abnormalities and fix them. One way to do so, is through the practice “Stop. Call. Wait”:

Stop – Associates are required to stop a process when they notice an abnormality.

Call – Associatesare required to call for help in resolving the issue.

Wait – Associates are required to wait on supervisor assistance before proceeding.

Ingrain this in your operation and culture: I will not accept bad quality. I will not create bad quality. I will not pass on bad quality.